What are Decarbonisation Strategies to Reduce Carbon Emissions in the Indian Steel Industry? - Economy | UPSC Learning

Topics

0 topics • 0 completed

🔍

No topics match your search

What are Decarbonisation Strategies to Reduce Carbon Emissions in the Indian Steel Industry?

Medium⏱️ 9 min read

economy

📖 Introduction

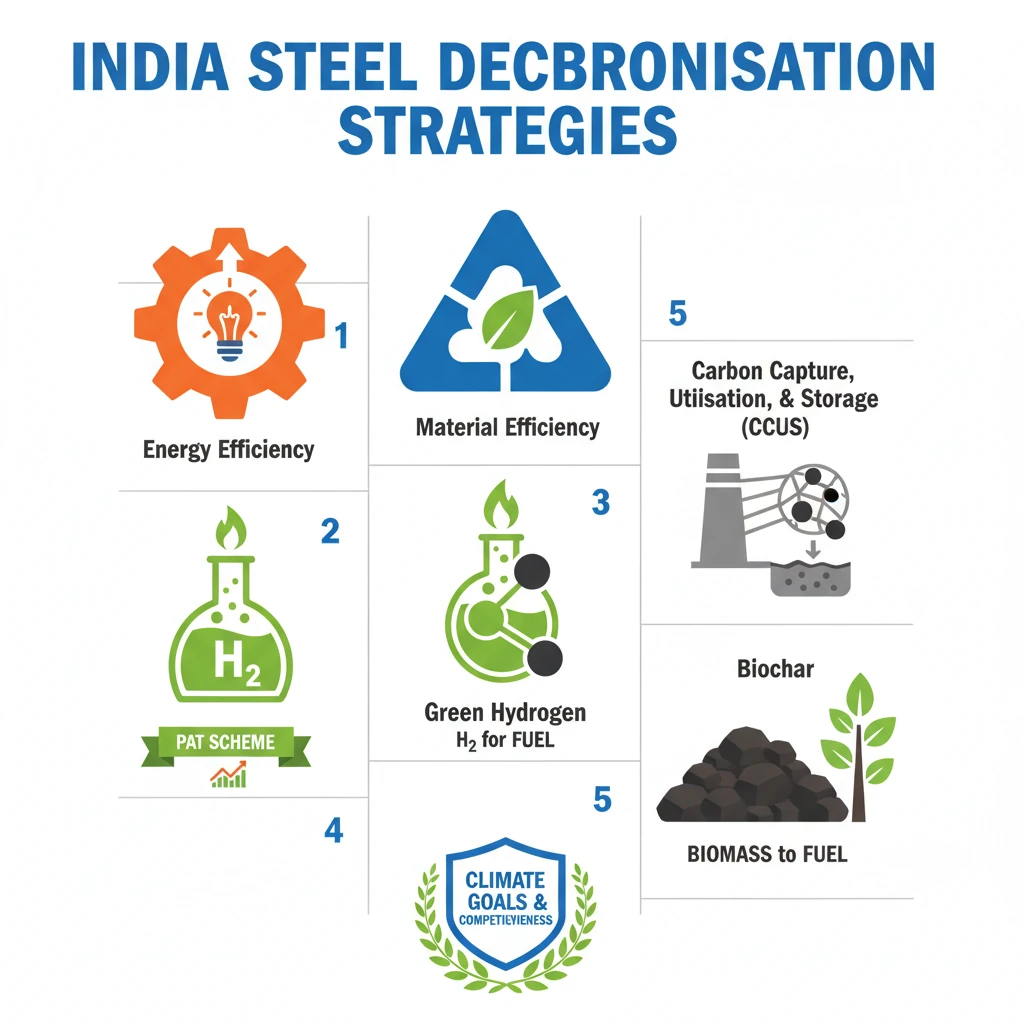

<h4>Decarbonisation Strategies for the Indian Steel Industry</h4><p>The <strong>Indian steel industry</strong>, a vital component of the nation's economy, is also a significant contributor to <strong>carbon emissions</strong>. Addressing this challenge requires a multi-faceted approach involving various innovative strategies.</p><p>These strategies aim to reduce the industry's environmental footprint while maintaining its growth trajectory and competitiveness. The focus is on adopting cleaner technologies and processes.</p><h4>Energy Efficiency (EE) in Steel Production</h4><p><strong>Energy Efficiency (EE)</strong> is a foundational strategy for reducing emissions. Improving energy utilization directly lowers the consumption of fossil fuels and, consequently, carbon output.</p><div class="info-box"><p>The <strong>Perform, Achieve, and Trade (PAT) scheme</strong> has been instrumental in driving significant <strong>energy savings</strong> within the sector. The scheme incentivizes industries to reduce their specific energy consumption.</p></div><p>Under the <strong>PAT scheme</strong>, the Indian steel sector has achieved substantial savings, reaching <strong>6.137 million tonnes of oil equivalent (Mtoe)</strong>. This figure notably surpassed the initial targets set for the industry.</p><div class="key-point-box"><p>Further reductions in <strong>energy intensity</strong> are achievable through the adoption of <strong>Best Available Technologies (BATs)</strong>. These advanced technologies offer superior energy performance.</p></div><p>However, challenges persist, including low penetration rates of <strong>BATs</strong>, constraints in <strong>retrofitting</strong> existing plants, and high associated <strong>capital costs</strong> for implementation.</p><h4>Material Efficiency Enhancements</h4><p><strong>Material efficiency</strong> focuses on optimizing the use of raw materials to reduce waste and energy consumption. This approach has a direct impact on the overall carbon footprint.</p><p>Enhancing processes like <strong>beneficiation</strong> and <strong>pelletisation</strong> of <strong>iron ore</strong> can significantly improve productivity. These improvements lead to a reduction in the consumption of <strong>coke</strong>, a major source of emissions.</p><div class="info-box"><p>The <strong>Ministry of Steel</strong> is actively considering providing <strong>incentives and support</strong> for the adoption of these advanced material efficiency technologies. This aims to accelerate their widespread implementation.</p></div><h4>Green Hydrogen Integration</h4><p><strong>Green hydrogen</strong> is emerging as a critical decarbonisation pathway, offering a clean alternative to traditional fossil fuels in steelmaking. It is produced through electrolysis powered by renewable energy.</p><p>It can effectively <strong>substitute fossil fuels</strong> in key steel production units such as <strong>blast furnaces</strong> and <strong>shaft furnaces</strong>. This direct replacement significantly lowers carbon emissions.</p><div class="key-point-box"><p>Exploration is underway for developing <strong>100% hydrogen-based direct reduced iron (DRI)</strong> processes. This represents a significant leap towards completely decarbonized steel production.</p></div><p>Leading Indian steel manufacturers like <strong>Tata Steel</strong> and <strong>JSW</strong> are at the forefront of research and development efforts in India to integrate <strong>green hydrogen</strong> into their operations.</p><p><strong>Hydrogen injection</strong> into furnaces can reduce <strong>coke consumption</strong> and directly lower <strong>CO2 emissions</strong>. This method offers an immediate benefit in existing infrastructure.</p><div class="info-box"><p>A significant increase in <strong>green hydrogen</strong> consumption is projected if its costs decrease to around <strong>USD 1/kg</strong>. Cost reduction is a key enabler for its widespread adoption.</p></div><h4>Carbon Capture, Utilisation, and Storage (CCUS)</h4><p><strong>Carbon Capture, Utilisation, and Storage (CCUS)</strong> is a crucial technology for achieving <strong>deep decarbonisation</strong>, especially in sectors with hard-to-abate emissions like steel.</p><div class="key-point-box"><p><strong>CCUS</strong> has the potential to mitigate up to <strong>56% of emissions</strong> from existing steel production technologies. This makes it a powerful tool for transitioning current plants.</p></div><p>India possesses some experience with <strong>CCUS</strong>, including the implementation of a few <strong>pilot projects</strong>. These projects are vital for understanding the technology's feasibility in the Indian context.</p><p>Significant obstacles to <strong>CCUS</strong> adoption include its <strong>high costs</strong> and the stringent requirement for <strong>high-purity CO2</strong> streams. These factors pose considerable technical and economic challenges.</p><div class="info-box"><p>The <strong>Ministry of Steel</strong> is actively exploring <strong>iron-ore green hydrogen-based CCU applications</strong>. They are also investigating new technologies such as <strong>carbon recycling</strong> to enhance CCUS effectiveness.</p></div><h4>Role of Biochar</h4><p><strong>Biochar</strong> presents an innovative and sustainable alternative for reducing carbon emissions in the iron and steel sector. It is derived from various forms of biomass.</p><div class="info-box"><p><strong>Biochar</strong> is produced from diverse <strong>biomass</strong> sources, including <strong>crop residues, bamboo, forest residues, and bagasse</strong>. This utilizes agricultural and forest waste streams.</p></div><p>It offers <strong>comparable metallurgical properties</strong> to traditional fossil fuels like <strong>coal and coke</strong>. This makes it a viable substitute without compromising steel quality.</p><div class="key-point-box"><p>The potential of <strong>biochar</strong> lies in its ability to <strong>partially or fully substitute</strong> these fossil fuels in steelmaking processes, thereby significantly reducing the sector's carbon footprint.</p></div><div class="exam-tip-box"><p>Understanding these diverse strategies is crucial for <strong>UPSC Mains GS-III Economy and Environment</strong>. Questions often focus on India's industrial decarbonisation efforts and sustainable development goals. Be prepared to discuss both the potential and challenges of each strategy.</p></div>

💡 Key Takeaways

- •Decarbonisation of the Indian steel industry is crucial for achieving India's climate goals and enhancing global competitiveness.

- •Key strategies include Energy Efficiency, Material Efficiency, Green Hydrogen integration, Carbon Capture, Utilisation, and Storage (CCUS), and Biochar.

- •The Perform, Achieve, and Trade (PAT) scheme has successfully driven significant energy savings in the steel sector.

- •Green hydrogen and biochar offer sustainable alternatives to traditional fossil fuels, reducing direct carbon emissions.

- •CCUS is vital for deep decarbonisation of existing plants but faces challenges related to high costs and technical requirements.

- •Government support, policy incentives, and continuous R&D are critical for accelerating the adoption of these green technologies.

🧠 Memory Techniques

95% Verified Content

📚 Reference Sources

•General knowledge on Indian steel industry and climate policy